Hydrogen Aerospace Expertise Rolls Royce

Rolls Royce plc. is the industry leader in building jet engines for the aerospace sector.

The Challenge

This project aimed to investigate the impact of hydrogen on metals used within a jet engine. The research focused on two key areas:

- Corrosion: How exposure to a hydrogen-rich atmosphere affects the component’s susceptibility to corrosion.

- Hydrogen embrittlement: How hydrogen exposure weakens the material, making it more prone to cracking and failure.

Our Research

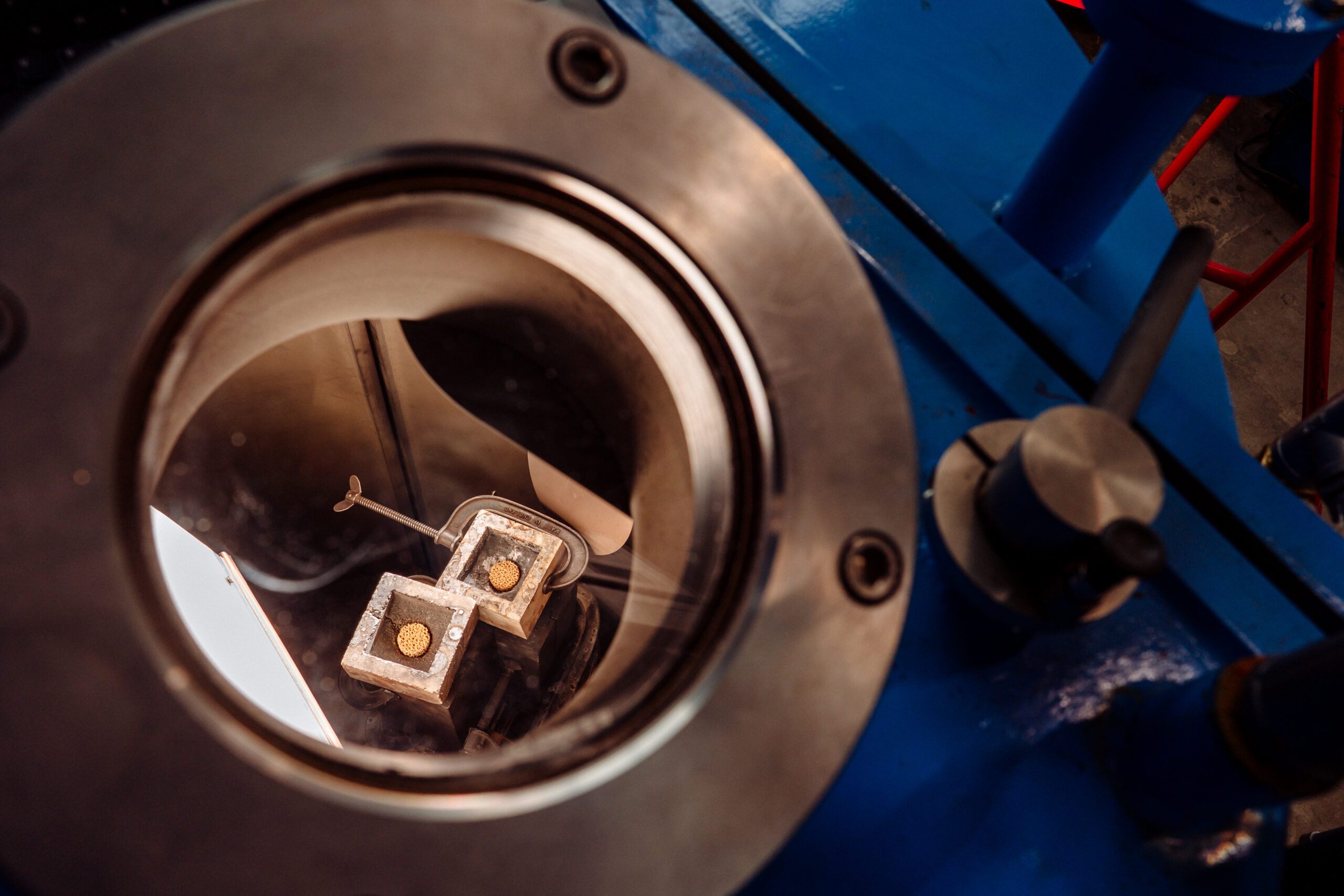

The SaMI team provided a design drawing as a starting point, outlining a chamber specifically designed for this experiment in our Sintec lab. Sintec stands for simulation and integrity testing in extreme conditions”. The facility enables process simulation and asset integrity testing of materials at very high temperatures in reactive gas environments such as hydrogen.

The chamber housed a metal specimen in the centre and exposed it to a controlled hydrogen-rich environment.

The metal specimen resembled a curved rod, as this closely matched the geometry of the component under investigation. The intention was to apply a specific bending force while simultaneously exposing it to the hydrogen atmosphere, allowing observation of the material’s behaviour under these combined stresses.

Solutions and Results

Our research collaboration resulted in the development of a specialised chamber capable of replicating the desired conditions (hydrogen atmosphere, bending force) for the specific metal component. Our research provided reliable testing data for Rolls Royce, ensuring the safety and integrity of new materials or designs in jet engines.

Mike’s unique knowledge in testing materials under hydrogen-rich conditions provided valuable insights for Rolls Royce, especially as the use of hydrogen in jet engines becomes a more prominent consideration due to decarbonisation efforts.

Benefits

Our relevant, niche, and unique expertise enabled us to understand, develop and deliver elaborate testing for Rolls Royce within a timescale that exceeded expectations. Safety is a priority in the design of jet engines, our insights provided with a level of certainty Rolls Royce deemed remarkable and exceptionally valuable.

Our accumulated extensive knowledge in the relatively new area of hydrogen provided Rolls Royce with reliable information to make some engine design calculations.

Industrial Decarbonisation

The aerospace industry has to meet UK government targets of zero emissions for domestic flights by 2040. The focus on hydrogen’s role in decarbonisation efforts underscores the growing importance of research in this area. Our research sheds light on the complex interaction between hydrogen and jet engine components, contributing valuable data for Rolls Royce in their development of safe and sustainable future engines.

The collaboration further develops SaMI’s expertise in hydrogen testing and characterising materials performance in hydrogen.

Thanks to contributor Dr. Juan Carlos Fallas-Chinchilla from Rolls-Royce.