Switch Steel

Steel and Metals Institute now Switch Steel

SaMI has evolved into Switch Net Zero Wales, a network of Welsh universities driving research and innovation for industry’s decarbonisation and Net Zero transition.

Visit Switch Net Zero Wales website

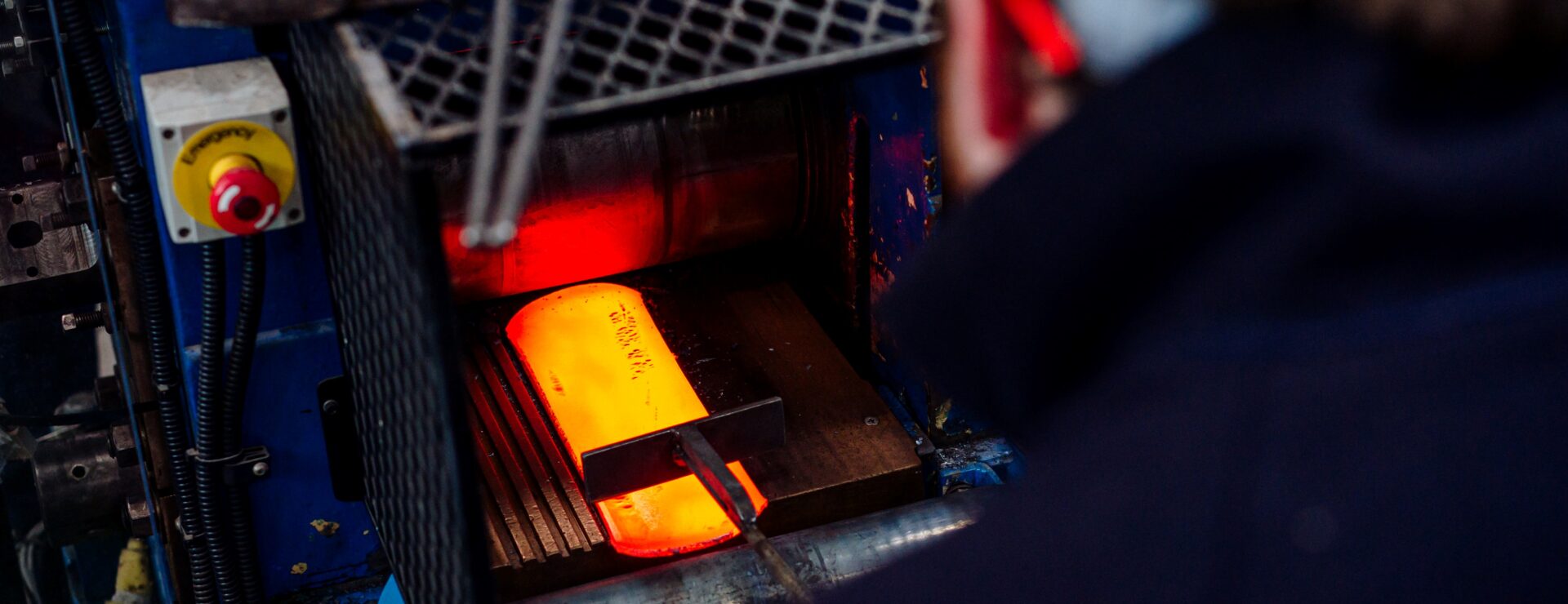

Delivering Practical Net Zero Solutions

We work with industry to deliver practical solutions for Net Zero. We specialise in industrial decarbonisation, drawing on our expertise in steel and metals to help other industries develop Net Zero materials and manufacturing processes. We have the right combination of expertise, skills and knowledge, equipment capability, and an adaptable environment to make this happen.

We create professional research and innovation partnerships, developing strong collaborations with industry through confidentiality, trust and an ability to listen. Our expertise is multi-disciplinary and we bring together an extensive network of expertise in Net Zero.

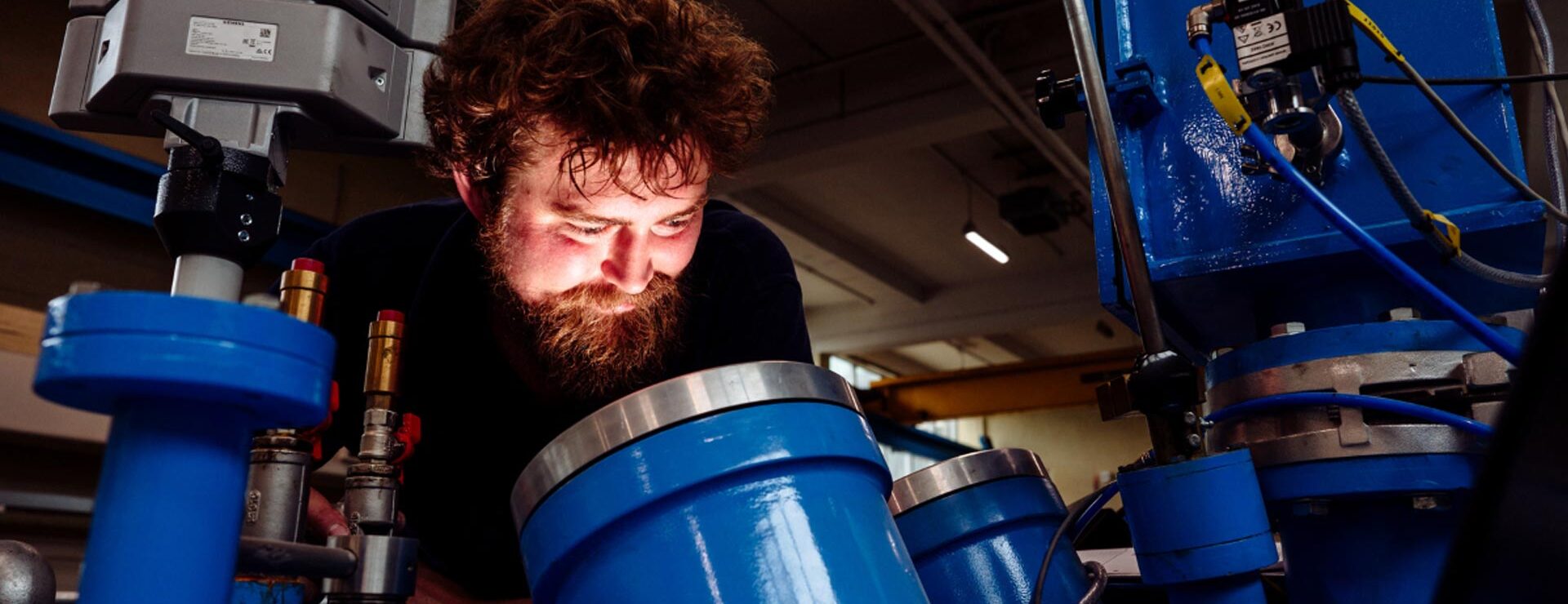

Working closely with industry we develop collaborative partnerships to deliver research and innovation solutions

We establish research partnerships with industry to meet decarbonisation targets and address Net Zero challenges. We can work with you on specific research solutions or collaborate on developing a publicly funded research opportunity. Our partnerships are flexible, so please get in touch to see what we can do and how we can work together.

Testimonials

Mark Cichuta, Ciner GlassWorking with SaMI’s research team has given Ciner Glass the confidence to further look to reformulate our glass product. Their expertise in product and process development from working with steel metals and other materials makes them the perfect partner to help us achieve our decarbonisation goals.

Dr. Juan Carlos Fallas-Chinchilla CEng FImechE, Rolls-RoyceWith hydrogen key for net-zero aviation, understanding hydrogen-metal interaction is crucial. This is Mike’s expertise. He precisely defined the necessary forces, currents, and electrical application. His knowledge of material testing and test rig design impressed us. Communication was seamless – regular meetings with prompt updates kept us informed. Understanding our time constraints, Mike consistently delivered the information needed. He is responsive and prompt, clarifying our questions, giving us the latest, and providing rigorous updates. Mike understands the time constraint and pressure to deliver this kind of work and was ahead of the game.

Neil Jenkins BSc MRICS, Director, Creo GroupCreo started manufacturing large steel hydrogen storage tanks and approached SaMI to test its designs for an internal coating system to prevent embrittlement of the steel in the tanks, in order to make them safer with longer lifespans. A strategy was formed, regular meetings were held and a final report was compiled. During this time, SaMI collaborated with us in the submission of Innovative UK grants and despite lengthy applications, tight deadlines were adhered to on each occasion. We would have no hesitation is using, working with or collaborating with the SaMI team again on steel or hydrogen projects.

Peter Warren, Development Metallurgist, British SteelMike Dowd has considerable expertise and experience and, uniquely, supplies a full results analysis with valuable insight. Between British Steel and Tata Steel we have worked closely with Mike to develop an updated test program to better replicate the reduction conditions in a modern blast furnace practice with both high coal and high gas injection rates. The standard of the work and analysis carried out by SaMI has been of the highest quality.

Dr. Chris Weirman, Technology Director, Wall Colmonoy LtdMike Dowd’s thorough understanding of the field of high intensity corrosion resistance has enabled the adoption of a range of testing criteria. Only working closely with SaMI would this testing be possible. This has afforded us the benefit of understanding the product’s performance to a more detailed level. We are extremely thankful SaMI’s approach allows an SME like us to have the option to research this data.