Simulating extreme environments

Our SINTEC facility is helping industry research net zero technologies.

Industrial process simulation

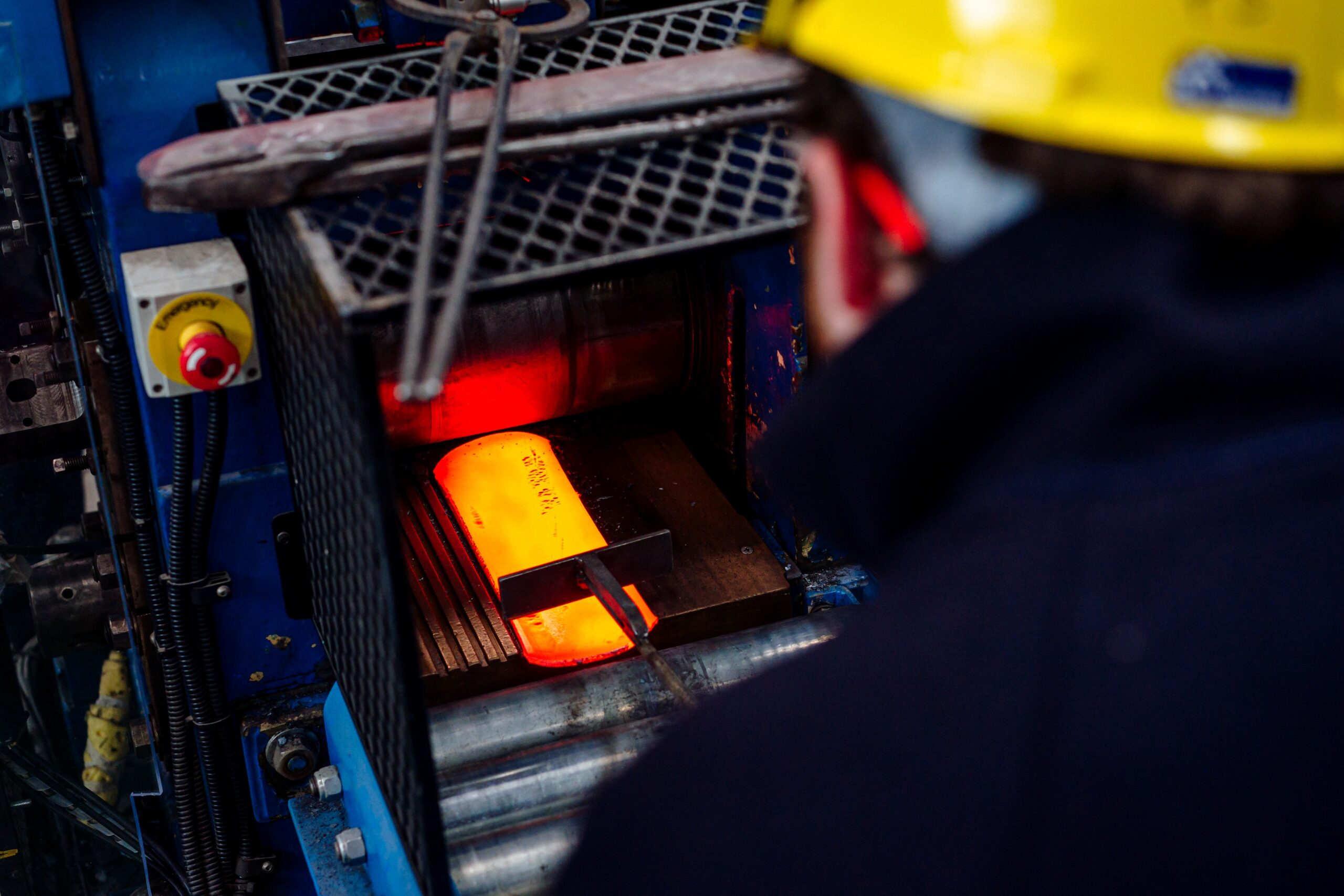

SINTEC is a globally unique facility that stands for “simulation and integrity testing in extreme conditions”. The facility enables process simulation and asset integrity testing of materials at very high temperatures in reactive gas environments such as hydrogen, carbon monoxide and sulphur dioxide.

By conducting experiments that simulate industrial processes in the lab we help industry research breakthrough alternative technologies to reduce carbon emissions and develop net zero manufacturing and materials.

Industrial decarbonisation experience

SINTEC’s facility manager Mike Dowd began his career as an aerospace engineer working with Rolls-Royce plc when aviation was facing significant pressure to reduce carbon emissions. He was simulating jet engine service environments on the lab scale, assessing the ability of materials to withstand the harsh operating conditions of civil engines in flight.

Mike has focused his knowledge and experience from aerospace on the decarbonisation of the steel and metals sector – both are carbon and capital intensive industries facing similar challenges. He conducts research on fuel switching to lower carbon or carbon free fuel sources. Mike and his team in SINTEC have conducted research on hydrogen and biomass in steelmaking and other industrial processes.

Extreme environments expertise

Mike now works with industry more broadly on net zero solutions and decarbonisation. The combination of SINTEC’s unique capabilities and Mike’s expertise provide dedicated and unique solutions to industry. Our team have developed a specific expertise in extreme hydrogen environments, delivering real hydrogen solutions to the aerospace industry.

We provide research and innovation solutions to companies that wouldn’t otherwise have access to our level of expertise. Working with start-ups and SME’s, as well as established and innovative companies such as Rolls Royce and Tata Steel, we are supporting several sectors to find practical solutions to manufacturing challenges.

Collaborating with our industry partners we deliver real decarbonisation solutions in the transition to net zero, helping Wales move towards a green economy.

Please contact us for more information about SINTEC.

Contributor Mike Dowd

Updated January 2024