Practical industry solutions

Dr Barrie Goode explains how SaMI collaborates to provide practical solutions for industry.

Industry needs to address governmental decarbonisation targets. By focusing our expertise in steel to help other sectors with similar challenges, we deliver customers practical solutions for long term sustainability, .

Innovating products and processes

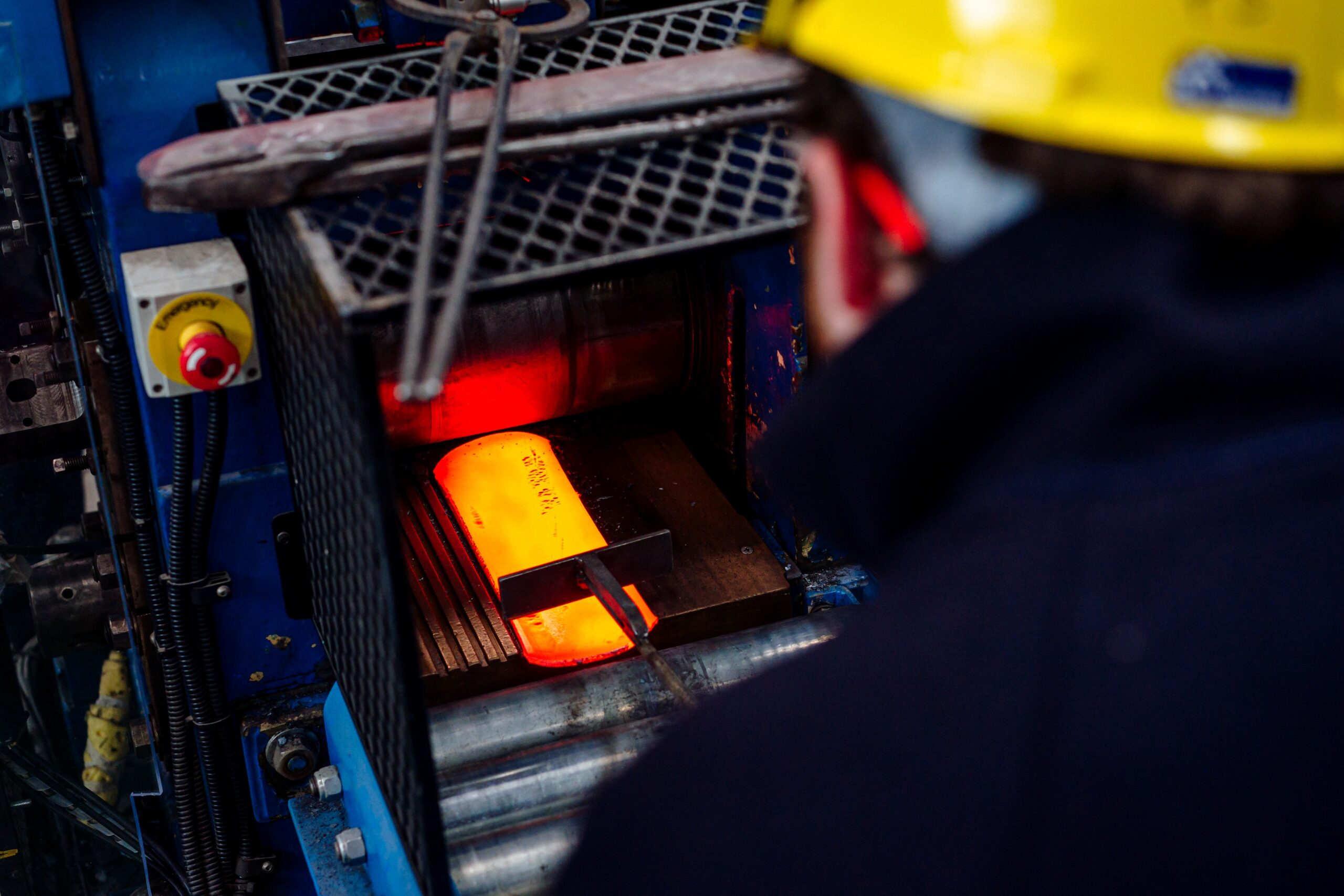

SaMI’s initial focus is steel innovation. Our research and innovation was founded in future proofing the UK steel and metals industry and it’s supply chain. Helping steel producers, suppliers and end-users adapt to challenges such as decarbonisation and net zero. This includes construction, energy and transport industries, as well as the steelmaking industry itself.

SaMI is unique as one of a few UK facilities to enable a full through chain simulation. We do a lot around alloy development, melting, rolling, pickling, and annealing. We’re testing and analysing products to ensure they meet specification.

Steel and the wider manufacturing industry have always invested in research and innovation. Decarbonisation of a carbon heavy industry is about helping companies to innovate processes and products. We help our customers innovate and modernise to become fit for the future. It’s about addressing the product lifecycle issues and the circular economy.

Practical research solutions

I think ‘practical solutions’ is the key thing here. The innovation we undertake with our industry customers is very much focused on helping them with whatever it is they need for more effective products and processes.

For example, steel producers who need effective alloy and downstream product and process development – that takes time and is expensive. It carries a lot of risk and involves processing high volumes of product.

We can simulate at pilot scale to minimise the risk of introducing new products at an industrial level. We can simulate the process at scale to enable companies to transfer to plant and go straight to production. And our customers know they can do so safely and effectively in a significantly shorter timescale than if they were doing this in-house.

Adaptable, bespoke approach

What our team do really well here at SaMI is adaptability in our approach.

There are plenty of organisations tackling steel innovation for example, but they tend to have bespoke expensive equipment. The problem with this is that this equipment cannot be easily maintained and adapted for future testing to address new problems and solutions. Therefore, these R&I organisations have limited their testing to a specific industry, processes and solutions that cannot then be adapted to other things.

We combine an established, extensive range of complex testing with the environment, knowledge and competency to design, test, and interpret. And provide a robust analysis of recommendations for companies to adopt. This capability applies to any industry innovating their products and processes, not just steel.

A unique approach

I don’t know of anyone else with the same approach as SaMI.

We combine expertise, equipment, and an agile approach to meet current and future innovation needs. We have the right adaptable environment, the people and kit with the capacity for research, to design, test, simulate and analyse alternative processes.

Our team come from a range of backgrounds with different disciplines, combining practical industry knowledge with academic expertise. It takes a long time to accumulate this knowledge and expertise. That cannot be quickly or easily achieved.

You combine this expertise with our approach to making small changes to kit to do something the equipment hasn’t been used for before, and I think that’s what is distinctive and unique about SaMI’s approach to research and innovation.

Contributor Dr Barrie Goode

October 2021